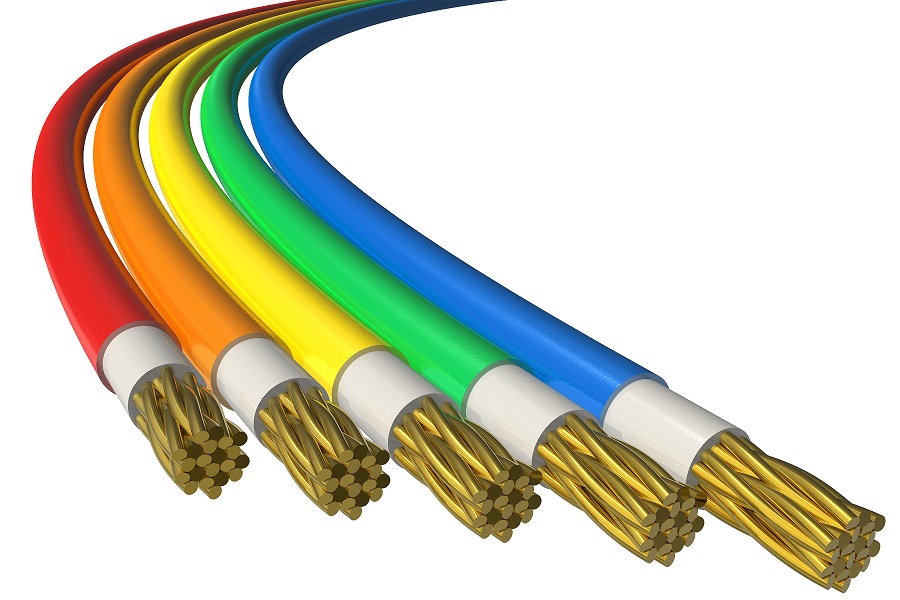

Copper is traditionally used by house wire manufacturers since so many years. Copper wiring offers numerous benefits. In case you plan on doing any wiring in coming future, you must include copper wire in to it. The several benefits that can be availed by using copper wiring in your wiring project are endless. In this article, we will discuss them for you.

- Best conductor

Among all the different metals and wire available today, copper is the best conductor. You can get more power in a piece of copper than any other metal you have. This is why it is most efficient material for making cables and wires.

- Flexibility

When you are using an electrical wire, you may need a flexible one. Usually house wires most likely have to bend around several different things. Copper wire is flexible yet tough. It is not brittle when you bend it around the things, so you don’t need to worry about any crack or break.

- High melting point

Copper takes really high temperature to get melt. So, if you are worried about safety, copper wire is the best option. If any overloading or surge comes through the wire, it won’t melt or burn the copper.

- Copper doesn’t loose

When you apply copper wiring at home, you are free from any replacement or repair thing in the future for years. When the wiring includes metal other than copper, they can sometimes loosen from the connection and come unattached. But this case doesn’t just happen to the copper wiring.

- Avoid incompatibility issues

Most appliance and electrical equipment producing companies mention that copper wire is in all of their products. That means when you have copper wiring in the home walls, you won’t encounter any incompatibility issues. Even if you try and use a non-copper wire up to a copper wire, it may cause a galvanic action and start some serious issue. By doing this, you may completely destroy the copper wire that is attached to. You may need to repair the whole system after this incident.

- Copper wiring is easy to work with

Most electricians prefer copper wiring for their projects due to convenience offered by the copper wire. They can strip it easily, pull it through tight spots, and don’t need to worry about surface oxides formation on it. Copper wiring is the best option for buildings.

- Lower coefficient of thermal expansion

Copper has a lower coefficient of thermal expansion. It measures the tendency of a material to alter its volume when temperature changes. This means copper wires do not sag or have destructive forces in joints.

- No corrosion

Copper doesn’t corrode. It is resistant to organic chemicals and can operate in most industrial environments. You may notice a green patina over the surface after long exposure to the atmosphere, but this is a protective layer and doesn’t affect the performance of copper wire.

- Easy to solder

Copper is the easiest metal to solder and thus, manufacturers use it n many applications that require good integrity.

- Less brittle and easy to install and repair

Copper cables are easier to install and to repair. Due to less brittle feature, house wire manufacturers use copper for 3-core cables as they have to be shaped and bent within cable ducts and enclosures.

If you want more updates on house wires or copper wires, you can contact manufacturers nearby your area. This article was solely issued to make you inform about the reasons why manufacturers use copper for production of their range of products. To share your feedback, kindly comment below.